April 14, 2024

Applying compelling, immersive simulation tech to build a better future

About Equinor: Equinor is an international energy company headquartered in Norway and operating in 30 countries worldwide.

Industry: Energy

Company size: 21,126 employees

Video: Simulation Technology Success: Equinor & Kongsberg Digital

As the leading operator on the Norwegian continental shelf (NCS), Equinor oversees the third-largest oil field, known as Johan Sverdrup.

With the entire field now being on-stream, it accounts for a third of Norway's oil production. So, optimising ongoing operations is important for the Equinor engineers stationed at installations across the site. But, key stakeholders face a range of critical challenges.

For instance, Operations Process Engineers must make sure facilities and plants run as efficiently and productively as possible.

Operations Process Technicians have to make sure that they – and their fellow control room operators – are prepared for any and every scenario.

Simulator instructors must know how to handle a range of different scenarios to help maximise safety and production. They also must be able to find and test different scenarios to optimise production.

Operations & Maintenance leaders must work to optimise production volumes through better efficiency. They also must catch errors and verify system solutions before start-up of the equipment.

And, the Head of Simulator Support needs to make sure all of these roles are getting the full value out of their simulators — so they, in turn, can be as effective as possible.

Equinor teams need to:

- Operate more efficiently

- Be prepared to handle any scenario

- Maximise safety

- Optimise production

- Verify system solutions

- Get full value from simulation technology

1. Apply simulation technology to run operations more efficiently.

Across heavy asset industries, simulators play a central role in keeping production efficiency high — and helping employees work safer and more sustainably.

Equinor’s Johan Sverdrup field shows how digital technologies and new ways of working can help address key challenges engineers and operators face, from startup through to production.

Before we dive into solutions for the challenges outlined above, consider some of the main benefits simulation technology can deliver for an organisation.

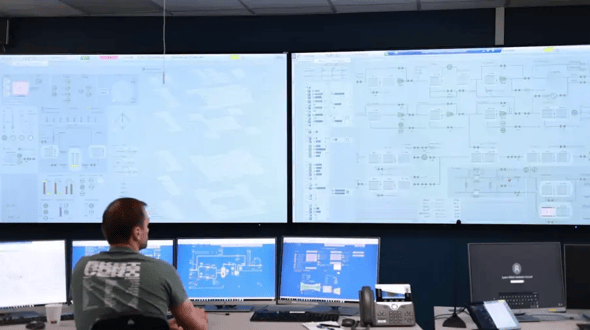

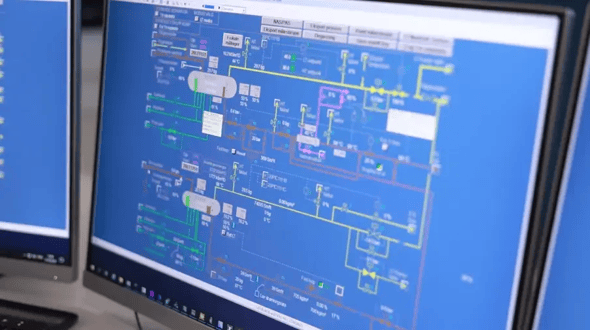

Certainly, simulation allows a team to represent an asset, facility, or worksite in a virtual format. But simulation also enables operators to track critical data from real assets through digital twin models — and facilitate immersive, real-looking scenarios that help operators become more knowledgeable and able to respond quickly to real-life situations.

With powerful technology like this, organisations operating in heavy-asset industries are better positioned to:

- Monitor production

- Boost safety conditions

- Cut energy consumption

- Increase efficiency

- Reduce emissions

- Create more value for their company

Simulations and models can help optimise production and improve energy efficiency. Plus, many ideas can be tested and questions answered.

In one project, for example, wells started to lose reservoir pressure and couldn’t produce to the topside inlet pressure. To maintain the same export rates, you would need to lower the topside inlet pressure. However doing so creates higher gas velocities, resulting in potential vibrations. It also strains equipment like compressors, coolers, and scrubbers.

Some questions that might be answered easily through simulation technology:

- Would it be safe to produce at a higher rate?

- What if we use a different valve?

- What if we lower inlet pressure?

By using the engineering study simulator, operators can determine if it is possible to maintain the same production rates at lower inlet pressures.

But in situations like these, the compressor might become a bottleneck. The Equinor team used this information to test and identify potential bottlenecks like the impact of coolers upstream and downstream. This makes it easier to target what they want to look at.

Video: Simulation technology for process engineers

For me, the strength of Kongsberg Digital’s simulators is the visualisation. It gives you a visual representation of what you're working with — and you can see and move through a known landscape.

Andreas Johannesen, Senior Engineer, Ops Process, Equinor

In the future, both process engineers and offshore workers will be able to open a simulator online, in the cloud, and conduct tests in real-time on assets.

So here, the simulation technology helps Equinor ensure that facilities and plants run as efficiently and productively as possible.

2. Make sure operators are prepared to handle any scenario.

In heavy asset industries, on-the-job training can be expensive, time-consuming, and in many cases just not feasible. Luckily, simulator technology is available to fill that gap and allow you to take training to an entirely different level.

Equinor uses simulators for all types of training. They use it to train new personnel — and to reinforce training for experienced personnel. They also use simulation both for normal process training and emergency preparedness training.

Video: Simulation technology for control room operators

Simulators not only demonstrate how a situation can happen in real life, but learners tend to remember things better from them. You become more familiar with processes and learn best by doing. The learners can also be evaluated for their responses more easily.

Svein Gunnar A. Haugen, Process Technician, Operations Process, Equinor

So, simulation technology enables control room operators to prepare for any and every scenario.

3. Maximise safety and production by knowing how to handle a range of different scenarios.

For an oil field operation like the one at Johan Sverdrup, operators need to maximise safety and production. As outlined above, that means being prepared to handle a range of different scenarios.

Those operators also should be able to test different ideas that either solve challenges or otherwise help optimise production. Here, the simulator becomes just the superpower they need.

Certainly, the simulators help improve their flexibility and response time. But operators can also better prepare for activities like shut-down and start-up.

In fact, Equinor's teams have been using Kongsberg Digital's simulators for many years to achieve many important tasks — like testing designs, testing logic, checking procedures, and training operators.

Scaling new heights: the Industrial Work Surface responds to operational demands

Video: Simulation technology for simulator instructors

We had an incident with a tripped low-pressure compressor on Kristin. The trip sequence failed, and we had a 4-hour lockout period for a gas turbine before we could start up again.

Knut Bolme, Process Engineer and Simulator Instructor, Equinor

When something like this happens, typically operators must close the wells to avoid flaring. Based on the original field design, normally the team would have had to hold off on start-up until they had the low-pressure compressor available again.

But based on their immersive simulator training the team could continue producing without any risk to their people or the environment. The procedure of switching from low-pressure to high-pressure production and back again at speed has been fine-tuned by using the simulator.

Some of the crew members had never done this operation live before. But I have been training for it on the simulator. Based on our training, we decided that we could start up in high-pressure mode. Production could continue at a reduced rate while waiting for the low-pressure compressor to be put back in operation.

Knut Bolme, Process Engineer and Simulator Instructor, Equinor

When the 4-hour lockout period was over, the compressor was started again and switched to low-pressure mode. The whole operation proceeded without any problems.

Lately, Equinor team leaders have made it easier for operators to access the simulator by placing it near the control room. That way, operators find it easier to learn and use the simulator.

With help from Kongsberg Digital, Equinor's production engineers and operators can constantly improve and modify the models so they represent their real-world assets in better detail.

4. Optimise production volumes through more efficient operations and maintenance.

Using Kongsberg Digital dynamic simulators in all phases of the project allowed Equinor to test and optimise activities early on. This enabled their teams to catch errors and verify system solutions before equipment start-up.

The ability to train their operators on simulators before the field was in operation resulted in highly-skilled staff, with greater confidence and fast response times.

In some instances when a project might have been close to shut down, operators were able to intervene quickly. They were ready to deal with unexpected and unlikely events, mainly due to training on a simulator.

Since the Johan Sverdrup field is so stable, the only way to keep operators prepared is through simulator training. This has led to some significant positive impacts for Equinor.

Significant impacts from simulation technology include:

- Safe and effective start-up

- Smooth transition to operational phases

- World-class production efficiency with high production volumes

The simulators play a vital role in training and exercises for operators and back office personnel, so everyone is better positioned to clean up alarm events, test logic, and improve the facility's performance.

The way we test logic on a simulator is important. We can thoroughly check and verify programming before putting systems into operation, and then use the online simulator to improve overall process performance.

Simulation enables you to fine-tune production by changing process parameters. You can also access key insights into problems so they can be resolved faster.

Together with other tools, the simulators help ensure high regularity so Equinor teams can meet the key sustainability KPIs around power usage and emissions that it is aiming for.

All in all, the simulators have been invaluable in helping us to get Johan Sverdrup up and running — and continue to help us work safer, smarter, and greener than ever before.

Jan Erik Lunde Senior Advisor O&M, Equinor

5. Get the full value from simulator technology

As the head of simulator support at Equinor, Hilde Hongset Gauslaa attributes their success to the quality of the simulator models and the close partnership they've established with Kongsberg Digital.

Hilde says she believes there isn't much value in just owning a simulator — and that you create value by using it. Also, these simulators must be reliable, accurate, and have fit-for-purpose fidelity and functionality.

“I have seen and felt the superpower of these tools.” –Hilde Hongset Gauslaa, Leader, Simulator Support Center, Equinor

She shares that Equinor teams can mitigate over 95% of all logic and software errors by testing it against a dynamic model of the installation. They also reduce a lot of time by testing off-shore by testing projects and modifications by virtual conditioning.

Now, Equinor is finding new ways to gain energy and production efficiency — and reduce their CO2 emissions.

To extract the full value from simulator technology, she advises that it's best to have a clear strategy.

Our strategy is to use the simulators in operations, projects, and modifications. We use Kongsberg Digital multiphase flow assurance models in our wells, pipelines, and risers.

Hilde Hongset Gauslaa, Leader, Simulator Support Center, Equinor

In areas like these, the value of the relationship between Equinor and Kongsberg Digital becomes much more clear.

If an Equinor team works with a model that does not have the right functions or fidelity, the Kongsberg Digital team takes action to solve it quickly. They understand how important it is that the simulators function correctly to keep the solution up and running.

Simulation technology changes the game for heavy-asset organisations

Simulators provide a secure and practical way for workers to gain hands-on experience in a realistic setting. This allows them to practise handling emergencies, develop critical decision-making skills, and explore and experiment with different approaches to common operational challenges.

By leveraging Kongsberg Digital's advanced simulation technology, Equinor's highly skilled workforce has been able to start up projects, perform modifications, and carry out shutdowns with fewer errors.

Equinor’s Johan Sverdrup field shows how digital technology and new ways of working can help energy companies address many of the key challenges they face, from start-up to production. With powerful technology like this, industrial organisations are better positioned to boost safety conditions, cut energy consumption, reduce emissions, and create more value for their company.

Having a clear strategy helps us extract the full value of the simulators. But training operators with simulators help you develop highly-skilled operations teams — with greater confidence and fast response times.

This has been a very valuable technology for us to use. From the example I mentioned, we avoided a production revenue loss of over 25 million Norwegian kroner.

Knut Bolme, Process Engineer and Simulator Instructor, Equinor

Simulators offer workers realistic training scenarios, enhancing their skills and knowledge to make more informed decisions. Applying Kongsberg Digital simulation technology has helped increase production efficiency, reduce unplanned production losses, streamline project schedules, and reduce start-up and communication issues.

Shaping the Future of Work Through Simulation Technology

See how the Equinor team uses simulation technology to achieve its goals faster and more efficiently.

Simulation Technology Can Change the Game

Applying the functionality of a simulator – in both tactical and strategic ways – can deliver significant benefits for industrial organisations. With powerful technology like this, you can boost safety conditions, cut energy consumption, reduce emissions and create more value for your company.

For example, Equinor engineers stationed at installations across the Norwegian continental shelf (NCS) have extensive experience with simulation technology. In fact, they have been using Kongsberg Digital's simulators to achieve many important tasks – like testing designs, testing logic, checking procedures, and training operators – for many years.

By leveraging Kongsberg Digital's advanced simulation technology, Equinor's highly skilled workforce has been able to start up projects, perform modifications, and carry out shutdowns with fewer errors.

By testing the logic in simulators before installing it on the platform, we can mitigate almost all logic errors.

CHALLENGE

How Can We Streamline Operations and Boost Safety?

Every day, workers in the energy industry encounter numerous challenges, including concerns regarding safety, environmental issues, and operational inefficiencies. How can technology help improve working conditions?

SOLUTION

Simulation Technology Shows You the Way

Simulators provide a secure and practical way for workers to gain hands-on experience in a realistic setting. This allows them to practise handling emergencies, develop critical decision-making skills and explore and experiment with different approaches to common operational challenges and new ways of working.

IMPACT

Model Safer, Smarter, and Greener Operations in the Real World

Equinor utilises Kongsberg Digital simulation technology to help their engineers work safer, smarter, and greener.

Maximise Safety

Ensuring the safety of on-site workers on Equinor's offshore platforms is of utmost importance. By conducting tests and simulations of various processes, including situational awareness and emergency preparedness, without affecting operations and facilities, workers gain a better understanding and improved competence. This instils a sense of security and confidence among workers that they can respond to real-world emergencies in a safe and efficient manner. Ultimately, this adds up to safer operations for all.

Work Smarter

Simulators offer workers realistic training scenarios, enhancing their skills and knowledge to make more informed decisions. Applying Kongsberg Digital simulation technology has helped increase production efficiency, reduce unplanned production losses, streamline project schedules, and reduce start-up and communication issues.

Operate More Sustainably

Simulators are a valuable tool for learning how to minimise waste, conserve resources, and reduce emissions. By using Kongsberg Digital simulators, Equinor was able to achieve a substantial reduction in energy usage.

Author

Kongsberg Digital

Kongsberg Digital is a provider of next-generation software and digital solutions to customers within oil and gas, chemicals and offshore wind. Its Industrial Work Surface, powered by the Kognitwin® platform, is redefining how industries work with data, insight and decision-making.